BACKGROUND

CP Cases design and manufacture high-performance, protective cases and 19" electronics racks used for transport, operation and storage of high value equipment in commercial and military applications. They have over 50 years experience in the design and production of cases and containers in welded aluminium, specialist rugged textiles and foam engineering.

Their most important and growing product is rotationally moulded containers (cases and 19" racks) which now account for over 50% of sales. The company’s USP is their capability for fast production of bespoke designs, low volume, high quality products and offer exemplary customer service.

CHALLENGE

To develop and embed a highly innovative rotational moulding facility to provide a step change in production efficiency, customer service and gross margins.

INNOVATION

CP Cases' vision is to be recognised worldwide, for their capability in the design and manufacture of protective case products with exemplary customer service. They currently export >70% of their products to 45+ countries. The company spent on average ~£500k PA with sub contract external moulders and continued to experience quality and delivery issues, despite working closely with them to maintain performance and output levels.

We worked on a technology transfer project to develop and incorporate Rotational Moulding technology within its production environment enabling them to have better process control, manage their own production, improve output, quality, meet customer expectations and ultimately increase profit.

RESULT

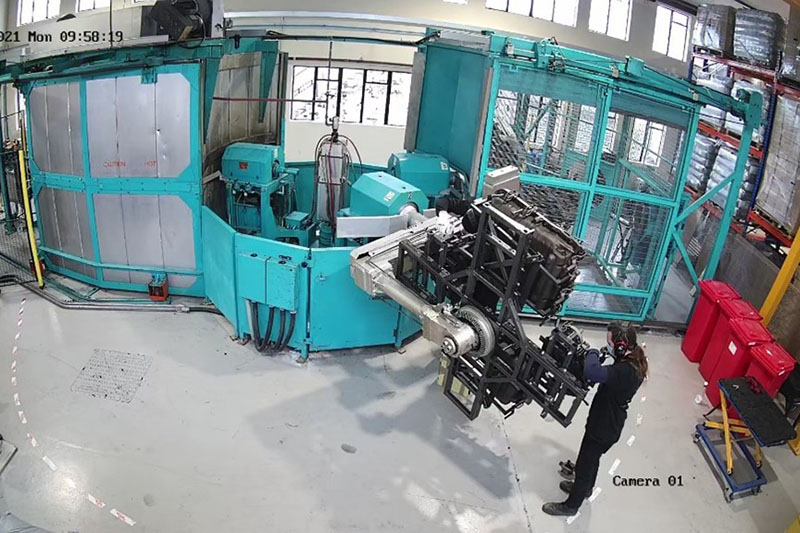

The results of the collaboration involved the installation and operation of a new rotational moulding production cell within the CP Cases factory.

IMPACT

CP Cases now produce the majority of their (previously sub-contracted) rotational moulded products. Follow-on collaboration has included a further Knowledge Transfer Programme on Digital Production and a collaborative project on the development of bio-sourced polymers for rotational moulding.

WHAT OUR CLIENTS SAY

"We have collaborated with the Polymer Processing Research Centre, AMIC, Queen’s University since 2018 to help us develop our new rotational moulding facility. We have benefited from the knowledge exchange and the expertise of all the team. We thought the distance would be a barrier as we are based in London but the project team was always very helpful and available to us with the technical and scientific advice. "